5 Days a week from 8:30 am to 5:30 pm

Customizing Grease Filters for Busy Commercial Kitchens

In the fast-paced world of commercial kitchens, every piece of equipment counts. Grease filters stand out as quiet heroes, trapping oil and grime to keep the air clean and machines running smooth. But off-the-shelf options don’t always fit the bill. That’s where customizing grease filters comes in. It lets you match them perfectly to your setup, boosting safety and workflow. This post dives into how customizing grease filters can transform your commercial kitchen. We’ll cover the basics, the perks, and practical steps to get it right.

Understanding Grease Filters in Commercial Settings

Grease filters do more than just catch drips. They pull in cooking vapors, snag fat particles, and stop buildup in vents and hoods. In a busy spot like a restaurant or hotel kitchen, smoke and steam build up quick. Without solid filters, that leads to greasy ducts, fire risks, and even shutdowns from health checks.

Think about a high-volume grill station. Oil splatters everywhere during rush hour. A standard filter might clog fast, slowing down exhaust fans. Customizing grease filters means building one that handles that exact load. It keeps the space fresh, cuts cleaning time, and helps staff focus on what matters—plating great dishes.

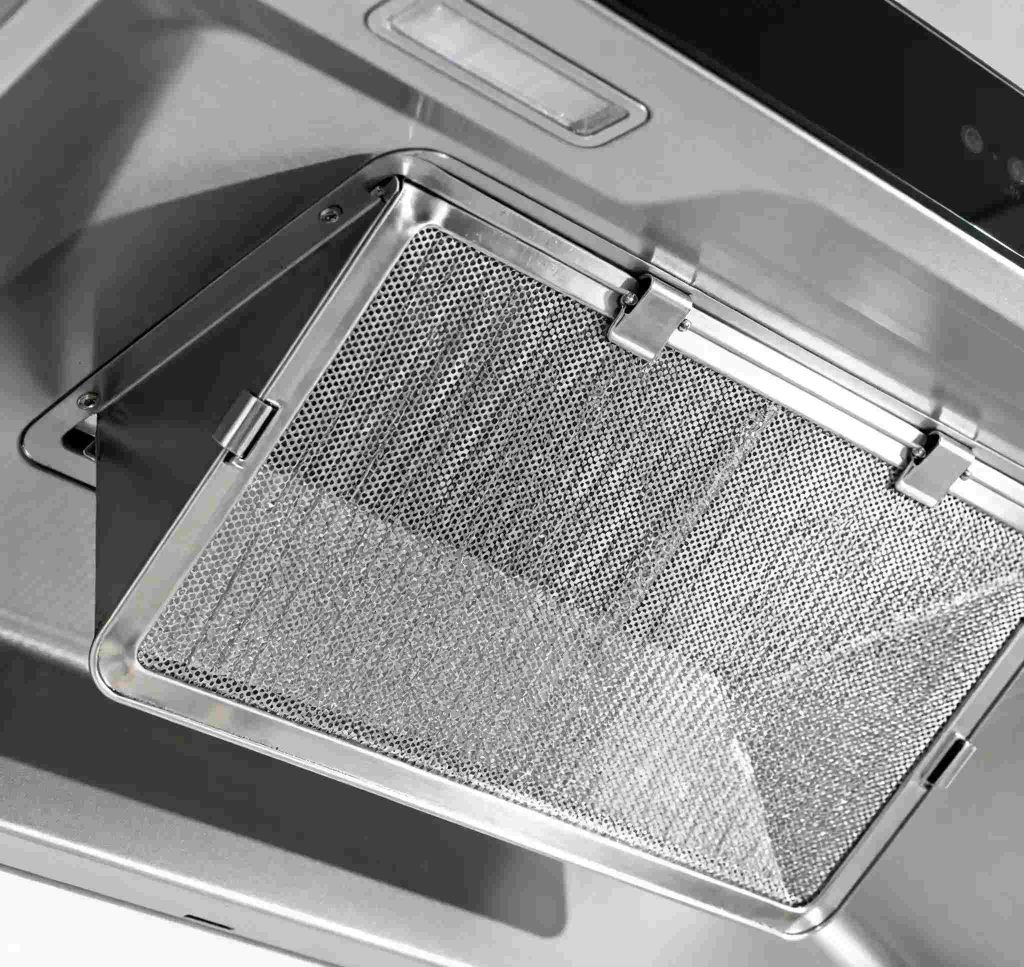

These filters fit right into range hood systems. They sit above stoves, pulling air through mesh or baffles. Over time, grease sticks, so easy removal for washing is key. In commercial kitchens, where codes demand regular upkeep, a tailored filter shines. It meets local rules while suiting your daily grind.

Why Bother Customizing Grease Filters?

Stock filters work fine for simple setups. But commercial kitchens vary wildly. A fast-food joint needs quick-drain designs for constant frying. A fine-dining spot might want sleek looks to match high-end gear. Customizing grease filters bridges that gap.

First off, it saves headaches. Imagine filters too small for your hood—they leak oil and make a mess. Tailored ones fit snug, cutting escape routes for grease. That means less scrubbing and fewer breakdowns.

Customization also boosts performance. You can tweak the mesh density for heavier oils from deep fryers or lighter ones from sauté pans. It pulls more air, keeps temperatures down, and extends hood life. In the end, your kitchen runs cooler and quieter.

Don’t overlook the brand angle. A custom filter with your logo etched in? It shows attention to detail. Customers notice a spotless setup—it builds trust. Staff feel proud too, knowing gear matches their workflow. For owners, it’s a smart move that pays off in smoother ops and repeat business.

Key Elements to Consider When Customizing

Getting customization right starts with picking the right features. It’s not just about slapping on a new size. You need to think through materials, build, and how it plays with your space.

Material Options for Durability

Stainless steel tops the list for grease filters in commercial kitchens. It fights rust, handles heat up to 500 degrees, and wipes clean easy. But not all steel is equal. Go for thicker gauges in high-heat zones to avoid warping.

Aluminum works for lighter duty, but it bends under heavy grease. Mesh types vary too—baffle filters with plates snag bigger particles, while fine screens grab tiny ones. Mix them for best results. A hybrid setup catches 90% more grease without choking airflow.

Here’s a quick comparison:

|

Material Type |

Best For |

Pros |

Cons |

|

Stainless Steel Baffles |

High-volume grilling |

Tough, easy clean |

Heavier weight |

|

Aluminum Mesh |

Lighter cooking |

Lightweight, cheap |

Less heat-resistant |

|

Hybrid Combo |

Mixed stations |

Versatile capture |

Custom cost up |

Pick based on your menu. Fried foods? Lean toward baffles.

Sizing and Shape Adjustments

No two hoods match. Customizing grease filters means measuring your exact space. Width, depth, height—all matter. A filter that’s off by an inch causes gaps where grease sneaks through.

Shapes flex too. Straight panels suit boxy hoods. Curved ones fit island setups. For tight corners, angled edges prevent blind spots. Add handles for quick swaps during shifts. That cuts downtime from minutes to seconds.

Test airflow early. A bad fit slows exhaust, trapping heat and fumes. Pros recommend mock-ups with cardboard before cutting metal. It avoids costly redo’s.

Boosting Filtration Power

Efficiency isn’t one-size-fits-all. Standard filters hit 70% capture. Custom ones push to 95% by layering materials. Add nano-coatings to repel oil—grease slides off instead of sticking.

Consider your exhaust setup. Long ducts need stronger pull, so beefier filters. Short runs? Lighter ones suffice. Factor in local codes too—some spots demand fire-rated baffles.

Bullet points for quick tweaks:

- Layer fine and coarse mesh for staged trapping.

- Embed quick-release clips for fast installs.

- Opt for dishwasher-safe panels to speed cleaning.

These changes make a real difference. Kitchens report 30% less grease buildup after switching.

Steps to Customize Grease Filters for Your Kitchen

Ready to dive in? The process is straightforward but needs planning. Start with your needs. Sketch your hood layout. Note peak cooking times and oil types. Chat with a supplier early—they spot issues you miss.

Next, prototype. Share drawings or photos. They’ll mock up a design. Test it in place. Run a full shift and check for leaks or clogs. Adjust as needed—maybe widen baffles or add drainage slots.

Production follows. Use quality steel, not thin sheets that dent. Weld seams tight for longevity. Once built, install with pros to meet codes. Train staff on care—wipe daily, deep clean weekly.

Budget-wise, custom runs 20-50% more than stock. But it pays back in less waste and longer life. Aim for modular designs. Swap parts without full replacements down the line.

Throughout, keep records. Note what works. It helps refine future tweaks. Many kitchens iterate yearly, staying ahead of menu changes.

How Custom Filters Elevate Your Commercial Operation

Beyond basics, customizing grease filters sharpens your edge. It ties into bigger goals like safety and sustainability. Cleaner air means fewer health complaints. Less grease in drains cuts plumbing calls.

For branding, think custom engravings. A filter panel with your eatery’s motif? It reinforces identity. Chefs love gear that feels personal—it boosts morale. Owners see it in reviews: “Spotless kitchen, top-notch food.”

Efficiency spikes too. Faster cleanups free staff for service. Reduced fan strain lowers energy bills. In a competitive scene, that adds up. Custom setups signal pro-level care, drawing partners and talent.

Look at chains—they standardize customs across sites. It streamlines ops and upholds quality. Solo spots gain the same polish without big spends.

Spotlight on Foshan Simple Technology Co. Ltd

Foshan Simple Technology Co. Ltd stands as a trusted supplier of grease filters for commercial kitchens. With over 15 years in the game, they craft pieces using solid tech and hands-on know-how. Their setup handles everything from raw cuts to final polish, keeping things tight on time and cost. Teams focus on OEM and ODM, turning your ideas into ready-to-use filters. From baffles to full hood kits, they deliver durable builds that fit real-world demands. Global reach means quick shipping, and their crew backs it with solid service. If customizing grease filters is on your list, they’re a go-to for reliable results.

Wrapping It Up

Customizing grease filters isn’t a luxury—it’s a smart play for any commercial kitchen chasing peak performance. It fits your flow, cuts risks, and polishes your brand. From picking materials to testing fits, each step builds a safer, smoother space. Dive in, and watch your operation hum.

Frequently Asked Questions

What makes customizing grease filters a must for commercial kitchens?

Customizing grease filters lets you match them to your hood size and cooking style. It traps more oil, keeps air fresh, and avoids clogs that slow down busy shifts.

How do I start customizing grease filters for my setup?

Map your kitchen first—measure hoods and note oil types. Then, team up with a supplier for designs. Test prototypes to ensure they handle your volume without gaps.

Can customizing grease filters save money in the long run?

Yes, it cuts cleaning time and extends gear life. Less grease buildup means fewer repairs, and efficient pulls lower energy use. Many spots see payback in under a year.

What materials work best when customizing grease filters?

Stainless steel baffles shine for toughness and easy wipes. Add mesh layers for better catch. Tailor to your menu—baffles for frying, finer screens for steaming.

How often should I check customized grease filters?

Wipe daily in high-use spots. Deep clean weekly to keep efficiency high. Custom designs with quick-access handles make it simple, fitting right into routines.