5 Days a week from 8:30 am to 5:30 pm

Why Bullet Feet Stand Out as the Best Support for Tough Kitchen Work

Running a heavy-duty kitchen means dealing with big loads, constant motion, and tough conditions every day. From sizzling grills to stacked shelves, stability keeps the chaos in check. Bullet feet have earned their spot as a top support solution for these spaces. If you’re a kitchen manager or chef, this post digs into why they’re a game-changer. We’ll cover their build, perks, and how they hold up under pressure—tailored just for your commercial kitchen needs.

The Need for Solid Support in Heavy-Duty Kitchens

Kitchens aren’t gentle places. Heavy gear rocks with use. Floors shift. Spills make things slippery. Without the right base, you’re asking for trouble.

What Makes Kitchens Tough on Equipment?

Think of a fryer packed with oil or a cooler stuffed with stock. Each weighs a ton. Add heat, steam, and foot traffic, and you’ve got a recipe for wobbles. Uneven tiles or worn concrete only make it worse. One jolt from a busy cook, and gear tips. Hot spills follow. That’s downtime and danger rolled into one.

Staff notice too. A shaky setup slows them down. They dodge unstable units, cutting focus on the food. Morale takes a hit when safety feels shaky.

Why Stability Beats Cost-Cutting Every Time

Skimping on supports saves upfront. But the bill comes later. A fallen shelf spills ingredients. A tipped oven burns a worker. Lost sales add up fast—think hundreds per hour in peak times. Repairs or replacements? More cash out the door.

Flip it. Good supports cut those risks. Fewer accidents mean lower insurance jumps. Staff stay sharp, turning out plates quicker. Customers keep coming back when service flows smooth. Your kitchen’s name grows as a reliable spot. It’s an investment that pays off.

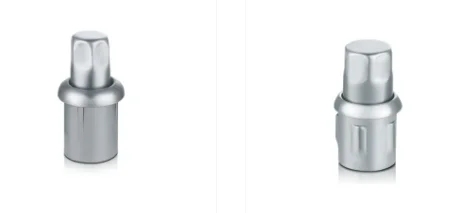

What Sets Bullet Feet Apart

Bullet feet aren’t just legs with a fancy name. Their design and strength make them a go-to for heavy-duty kitchens.

Built Tough for the Long Haul

These supports start with a solid core—often metal like aluminum or steel. That gives them grit to handle 600 pounds or more per set. Wrap that with a stainless edge, and you’ve got rust-proof armor against steam and splashes.

The shape helps too. A compact base, maybe 1.5 by 1.5 inches, slips under tight spots like counters or carts. No bulky overhangs to snag feet or hoses. It’s sleek but sturdy, fitting where taller legs can’t.

Adjustable Fit for Any Floor

No kitchen floor is perfect. Bullet feet adjust to that. Twist the base, and you gain an inch or two—enough to level a sink on a slanted tile or a shelf over a cracked slab.

This flex saves time. No shimming with scraps or grinding down bases. Set it, test it, done. Staff can focus on cooking, not wrestling gear into place.

Grip That Holds Through Chaos

The bottom’s where magic happens. A rubber cap or coated ring sticks like glue. Even on greasy floors, it grips. Some add a spring to soak up bumps from carts or drops.

This means no sliding when someone leans on a workbench. No rattling when a mixer hums. Stability keeps tools steady—knives don’t slip, pots don’t dance.

Real-World Wins in Heavy-Duty Kitchens

Bullet feet shine where the action never stops. Here’s how they stack up in the heat.

Holding Up Under Load

Picture a prep table loaded with 500 pounds of veggies and cuts. Bullet feet take it without a groan. Their spread base spreads weight even. No sagging mid-shift.

Ovens and grills? Same deal. Heat warps cheaper supports. These hold firm, keeping burners level. Food cooks right— no uneven sear marks to toss out.

Easing Cleanup and Moves

Kitchens get messy. Bullet feet lift gear just enough to sweep under. No trapped grease or grime. Wipe down, and you’re set.

Need to shift for a big event? Their low profile lets carts roll past. Adjust height on the fly. Rearrange without a full teardown. It’s a time-saver when minutes count.

Feedback from the Trenches

Chefs swear by them. One ran a busy diner and swapped old feet for these. “No more wobbles on my grill,” he said. “Staff move faster, and we’ve cut spills by half.” Another from a hotel kitchen noted, “They handle steam like champs. No rust after months.”

Reviews echo this. Customers praise the easy setup and solid feel. One called it “a small change with big calm.”

Picking and Caring for Bullet Feet

Getting the right fit and keeping them solid takes a little know-how.

Choosing the Right Size and Load

Match the load first. A 600-pound rating suits most units—shelves, sinks, light ranges. Heavier? Look for 800 pounds or more.

Size matters too. A 1.5-inch base fits tight spots. Wider ones, maybe 2 inches, handle bigger gear. Check your floor. Smooth concrete? Standard works. Rough or wet? Go for extra grip.

Setting Up for Safety

Bolt them square to the base. Use a level—bubble dead center. Test with weight after a day. Heat can shift things.

Space them right. Four per unit for balance. Cluster under heavy corners.

Train your team. Show how to spot a loose fit. A quick check beats a crash.

Keeping Them in Top Shape

Wipe bases weekly. Grease builds fast in kitchens.

Tighten threads monthly. Vibration loosens them over time.

Swap worn caps yearly. Fresh rubber restores grip.

Log checks. A notebook tracks tweaks. Catches issues early.

This routine builds trust. Staff rely on steady gear. Accidents drop.

Foshan Simple Technology Co.Ltd: A Reliable Bullet Feet Supplier

For kitchens needing top-notch support, Foshan Simple Technology Co.Ltd stands out as a solid choice. With 15 years crafting kitchen gear, they specialize in bullet feet built for heavy-duty use. Their designs handle moisture, heat, and big loads, tailored for commercial spaces like prep areas and cook lines. They offer custom logos and fast shipping to spots worldwide, backed by a skilled team and tight supply chain. It’s support you can count on to keep your kitchen running smooth.

Wrapping It Up: Why Bullet Feet Rule Heavy-Duty Kitchens

Bullet feet deliver where it counts—stability, adjustability, and grit under pressure. They lift your gear above chaos, cut risks, and boost workflow. Pick smart. Care right. Watch your kitchen thrive. It’s a small swap with big wins for you and your crew.

Frequently Asked Questions

What makes bullet feet a top support solution for heavy-duty kitchens?

Their tough build and grip hold big loads steady. Adjusts to floors, keeps gear safe.

How do bullet feet work best in heavy-duty kitchens?

Bolt them level. Space right. They handle weight and bumps without slipping.

Can bullet feet handle steam and spills in heavy-duty kitchens?

Yes. Stainless edges and rubber bases fight rust and stick through wet shifts.

How often should I check bullet feet as a top support solution in heavy-duty kitchens?

Wipe weekly. Tighten monthly. Swap caps yearly. Keeps them solid.

Are bullet feet easy to set up as a top support solution for heavy-duty kitchens?

Yep. Twist to fit. Level quick. Takes minutes, saves hassles.