5 Days a week from 8:30 am to 5:30 pm

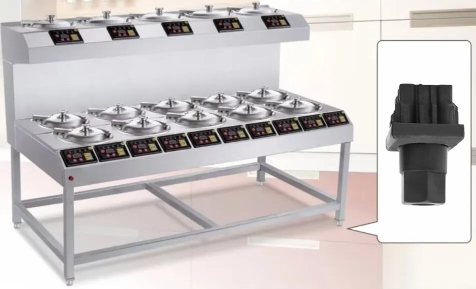

Your Ultimate Guide to Buying Bullet Feet for Commercial Kitchens

Running a hectic commercial kitchen means handling heavy gear that has to stay steady and even on bumpy floors. Bullet feet are those little but strong changeable legs that fix to the bottom of tables, sinks, and other stuff. They keep everything firm, safe, and simple to wipe down. If you’re putting together or fixing up a restaurant, hotel kitchen, or food making spot, choosing the right bullet feet can change things a lot in everyday work. This guide takes you through all you need to know to make a good pick.

Picture it. In a quick-moving kitchen, shaky counters cause spills, mishaps, and lost time. Bullet feet solve that by letting you change the height just so. They’re not showy, but they quietly hold up the whole thing. We’ll talk about what they are, why they count, and how to pick ones that match your setup.

Why Bullet Feet Matter in Busy Kitchens

Commercial kitchens deal with steady wear. Floors turn slippery from water and oil. Gear moves under hard use. But bullet feet give that added hold and changeability to manage it all. They stop tipping, which keeps workers safe and food work smooth.

Think of getting ready for a meal rush. An uneven table might mean blades sliding or items falling. Solid bullet feet lock in steadiness, cutting those dangers. And they make cleaning simpler by raising gear off the ground, so grime doesn’t pile up below.

Key Features to Look For in Bullet Feet

When looking for bullet feet, think about what fits your kitchen’s needs. Not all are alike. Some take heavy weights better, while others fight dampness or change easily. Here’s a quick look to help you choose.

Material Choices for Durability and Hygiene

Materials make a big difference in how long bullet feet hold up and how well they suit a kitchen spot. Stainless steel shines for its power and rust fighting. It deals with wet places without falling apart, which is important in areas near sinks or washers.

Rubber kinds give nice grip on slick floors. They soak up bumps too, lowering noise and shakes from blenders or stoves.

Choose based on your kitchen’s daily push. A lively eatery might want steel for lasting power, while a small shop could pick rubber to save cash.

Adjustability and Height Options

Height changing is a real help. Most bullet feet let you tweak from a bit up, making sure surfaces stay even on rough floors. Look for ones with easy threads that turn without tools.

In business spaces, rules often say gear must sit a set height off the ground for cleaning. Changeable bullet feet follow those without trouble. They also fit different worker sizes, making jobs comfier.

Try this. Twist in a set and feel it. A good one changes fast, staying tight once done. This bendability keeps your kitchen going without endless fixes.

Load Capacity and Stability Factors

Don’t forget weight limits. Heavy stoves or coolers need bullet feet that carry big loads, like up to 500 pounds each. Check details to fit your stuff.

Steadiness comes from the base shape too. Wider bases share weight better, stopping shakes. In damp kitchens, no-slip parts add safety. It’s basic: tougher feet mean less accidents.

Benefits of Using Bullet Feet in Commercial Kitchens

Bullet feet do more than hold stuff up. They improve work flow and cut costs over time. Let’s see why they’re a good buy.

Enhancing Safety and Workflow

Safety comes first in any kitchen. Bullet feet lower slip chances by keeping gear steady. No more running after moving carts in rush times.

They boost air flow under stuff too, helping stop mold or bugs. Clean floors stay that way longer. Workers can think about cooking, not mending wobbly tables. Food goes out quick because all is even and secure. That’s the plus bullet feet bring.

Long-Term Cost Savings

At first, they look like a small extra. But later, they save money. Tough ones last years, skipping often swaps.

They guard floors as well. Without them, heavy gear marks tiles or dents wood. Bullet feet soften that hit. It’s a clever way to keep things running without added spends.

Compliance with Industry Standards

Kitchens have to meet health rules. Bullet feet help by lifting gear for easy sweeping. Many places need at least six inches space.

Pick ones okayed for food work. They fight germ build-up, keeping your area clean. This grows trust with eaters and checkers.

Step-by-Step Guide to Purchasing Bullet Feet

Set to buy? Follow these steps for an easy go. It begins with checking your needs and ends with fitting tips.

Assessing Your Kitchen’s Needs

Walk your area. Note what gear needs feet – tables, racks, sinks? Measure floor bumps.

Think of crowd. Busy spots need stronger kinds. Money counts too; mix quality with what you can pay.

Write it down:

- Gear types

- Floor state

- Daily use level

This cuts choices quick.

Comparing Suppliers and Options

Not all sellers give the same. Seek those with history in kitchen stuff. Read what other workers say.

Match prices, but think of quality. Low-cost feet might break soon, costing extra after.

Ask on guarantees. Good ones cover flaws for years.

Installation and Maintenance Tips

Fitting bullet feet is easy. Most twist right in. Use a tool for snug fits.

For upkeep, wipe them weekly. Look for wear each month. Swap if threads wear or bases split.

Handy hint: Keep extras around. Stop time hurts in a kitchen.

Common Mistakes to Avoid When Buying

People mess up at times. Here’s what to skip.

Buying without measuring causes bad fits. Always check sizes first.

Forgetting materials? Damp kitchens need rust-proof ones, or they rot quick.

Missing weight checks risks falls. Fit to your heaviest things.

Advanced Considerations for Pro Kitchens

For bigger jobs, think wider. Custom matches for weird shapes. Big buys for chains.

Green choices are out there, like reused stuff. They draw in earth-friendly places.

Mix with other stuff. Bullet feet work nice with rolling wheels for movable sets.

Customization for Specific Kitchen Layouts

Fit to your floor plan. Slanted feet for tilted spots. Extra high for tall counters.

This personal touch improves work. Workers move easier, output grows.

About Foshan Simple Technology Co. Ltd as a Bullet Foot Supplier

Foshan Simple Technology Co. Ltd shines as a trusty seller of bullet feet made for commercial kitchens. With more than 15 years in it, they think on top materials and clever shapes that fit real needs. Their group manages all from raw checks to end items, keeping things steady. They send worldwide, helping kitchens in Europe, the Middle East, and more. Set on buyer happiness, they give answers that mix lasting with easy use, making them a top pick for workers wanting sure stuff.

Conclusion

To sum up, bullet feet may look small, but they ground your commercial kitchen’s win. By picking smart – thinking on materials, changeability, and match – you make a safer, better spot. This guide gives you the info to choose ones that last and work. At last, good bullet feet hold not just gear, but your full business feel. They quietly lift daily jobs, letting you stand out in a tough field.

FAQs on Bullet Feet for Commercial Kitchens

What exactly is a bullet foot in a commercial kitchen setup?

A bullet foot is a changeable leg that fixes to the base of kitchen gear like tables or sinks. It helps even things on bumpy floors and gives steadiness in hard use.

How do I choose the right bullet foot for my kitchen’s needs?

Begin by looking at your gear’s weight and the floor kind. For wet spots, pick rust-fight materials. This complete purchase guide says to match weight hold and changeability to your daily work for the best match.

Are bullet feet easy to install and maintain?

Yes, most twist on without special tools. Upkeep means steady cleaning to keep them holding. Using a complete purchase guide helps you pick ones that stay good over time.

Why should I invest in quality bullet feet?

They stop mishaps, make wiping simpler, and stretch gear life. In hectic spots, they’re main for smooth work, as shown in any good complete purchase guide.

Can bullet feet handle different floor surfaces?

Sure. Rubber ones hold slick tiles, while steel fits concrete. Shape your pick on your area to get the most from them.