5 dagen per week van 8:30 tot 17:30 uur

Common Problems with Bullet Feet and Ways to Fix Them in Busy Kitchens

Kogelvoeten help keep things steady and working well in big kitchen setups. You find them on work tables, ovens, fridges, or other tools. They make sure everything stays even and safe. This matters a lot in places where you need to be careful and exact. But like any kitchen part, bullet feet can have troubles after a while. This post looks at usual troubles in big kitchens with bullet feet. It also gives simple fixes to sort them out.

What Bullet Feet Are and Why They Matter in Big Kitchens

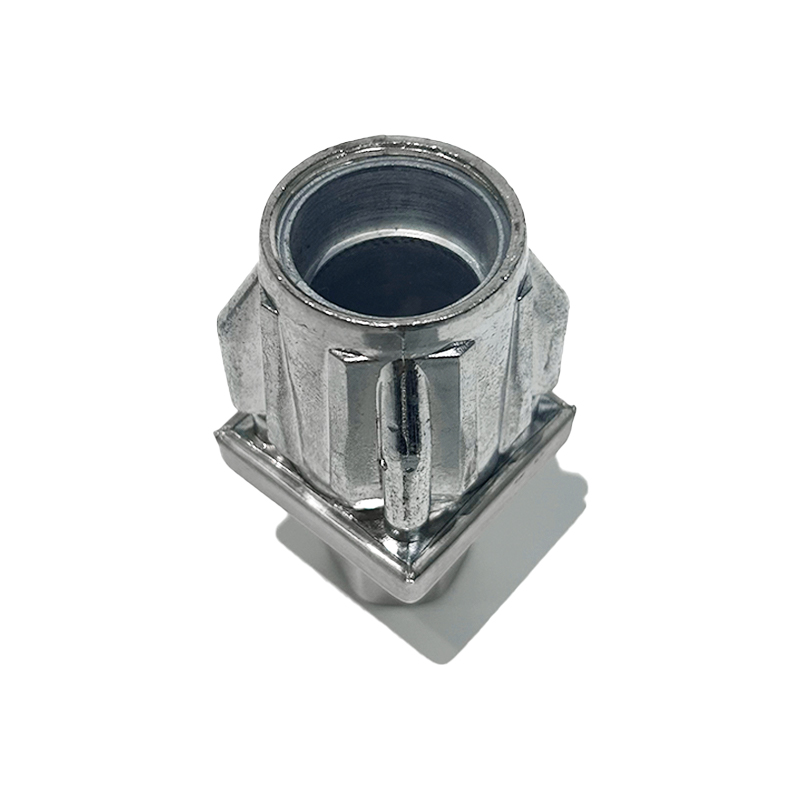

Bullet feet are feet you can change. They often come in stuff like strong steel or rubber. People fit them to kitchen tools to hold them up and keep them firm. Their big job is to make sure machines stay flat, even on bumpy floors. This helps a ton in busy kitchens, where you want things quick, safe, and tough. Bullet feet cut down shakes, stop slides, and guard the ground from harm by heavy stuff.

Usual Troubles with Bullet Feet in Big Kitchens

Even though they help a lot, bullet feet can run into snags that mess with how a big kitchen runs. Here are the top troubles big kitchens deal with bullet feet. I also share fixes to help sort them.

1. Hard Time Changing Bullet Feet

Trouble:

A big issue with bullet feet is how tough they can be to tweak. After some time, the twist parts on the foot get jammed with oil, dust, or junk. This makes it hard to spin or shift the feet. It gets really annoying when you try to even out tools on rough floors.

Fix:

To stop this snag, clean the bullet feet often. Grab a gentle brush to wipe away junk from the twist parts. Use a cleaner to get rid of any oil pile-up. If the feet still stick, put a bit of slick oil on the twist parts for easier moves. For certain kinds, try a tool like a changeable wrench to twist the feet. It gives more push.

More on this: In a fast kitchen, dirt builds quick from spills and steam. So, make cleaning a habit each week. This keeps things smooth and saves time later.

2. Tools Still Shaky After Putting in Bullet Feet

Trouble:

Even when you put bullet feet in right, some big kitchen tools might feel wobbly or unsteady. This could come from bumpy floors, wrong setup, or feet not tweaked well.

Fix:

Start by checking if the bullet feet sit right and get tweaked. See if each foot locks tight and lines up with the tool. For rough floors, pick longer feet you can change. They give more room to even things out. In bad spots, think about ground pads or special fixes to balance the slope from the floor.

Extra tip: Walk around the tool and push on corners. If it rocks, tweak the feet one by one until it sits flat. This simple check can spot issues early.

3. Bullet Feet Get Worn Out

Trouble:

Big kitchens see lots of action, and bullet feet wear down over time. Rubber ones might split or lose hold, while metal ones could rust or break down. This wear makes tools lose their steadiness and hurts how they work.

Fix:

Look over the bullet feet often, mainly if they handle heavy jobs. Swap out old or hurt feet fast to keep tools steady. For rubber feet, watch for splits or hard spots and change them when needed. Stainless steel feet need checks for rust signs. Get rid of any rust with a good cleaner or swap the feet fully.

Why this happens more: Floors get wet, and feet rub against them daily. In hot spots near ovens, heat speeds up wear. So, pick feet made for your kitchen type.

4. Rust on Stainless Steel Bullet Feet

Trouble:

Stainless steel bullet feet often get picked for big kitchens because they stay strong and last. But wet spots, oil, and strong cleaners can cause rust after a bit. This cuts their power and shortens how long they work.

Fix:

To dodge rust, clean and dry the bullet feet a lot, mainly after they touch water or cleaners. If rust shows up, use a soft cleaner to rub it off lightly. In tough cases, change the rusty feet with fresh ones to keep things steady and safe.

A bit more: Pick feet with extra coats against rust if your kitchen stays damp. This adds years to their use.

5. Sounds or Shakes Troubles

Trouble:

Bullet feet aim to cut shakes and sounds from tools running in a big kitchen. But after time, they might not soak up bumps or quiet noise well. This leads to extra sounds that bug kitchen workers and mess with the work spot.

Fix:

If sounds or shakes turn into a problem, maybe switch to fresh bullet feet made for cutting shakes. Rubber or soft-coated feet can take in more bumps and lower noise. Or, put soft pads under the feet to drop shakes even more.

How to test: Run the tool and listen. If it rattles, check feet first. Loose ones often cause this.

Ways to Keep Bullet Feet Good for Longer

Stopping the troubles above needs steady care. Here are tips to make sure your bullet feet stay fine:

- Clean Often: Keep bullet feet clear of oil, dust, and other junk. Pick a light cleaner and a soft brush to wipe them without harm.

- Check for Wear: Look now and then for wear signs, rust, or splits. Spotting early lets you fix before it hurts tool steadiness.

- Tweak Right: Make sure feet get changed well and the same. This keeps tools flat and firm in use.

- Swap Hurt Feet: If any bullet feet look worn or too hurt to fix, change them right away to stop more snags.

Plus, think about your kitchen flow. Busy spots need tougher feet. Train staff to spot issues too.

Meet Foshan Eenvoudige Technologie Co.Ltd

At Foshan Eenvoudige Technologie Co.Ltd, we focus on giving top bullet feet made for big kitchen spots. Our items, like feet you can change from tough stuff, aid kitchen folks in keeping steady and running smooth.

For extra info on our items, check our product center or talk to our group about what you need.

Wrap Up

Bullet feet help a bunch in keeping things steady and safe in big kitchens. They usually work well, but troubles like hard tweaks, wear, rust, and sounds can pop up over time. By checking and caring for these parts often, kitchen bosses can make sure their tools stay flat, firm, and safe.

Quick Questions

1. Why do my bullet feet loosen up?

Bullet feet can get loose from tool moves or bad setup. To stop it, lock them tight when you put them in and check often for firmness.

2. Can I switch rubber feet to stainless steel?

Sure, you can change rubber bullet feet to stainless steel. Those work great in spots needing more toughness or wet areas.

3. How to tell if bullet feet need swaps?

If feet show clear wear, splits, rust, or don’t hold steady, time to change them.

4. Do bullet feet fight rust?

Stainless steel bullet feet mostly hold up against rust, but strong cleaners and wet can still cause it over time. Steady cleaning and care can make them last longer.